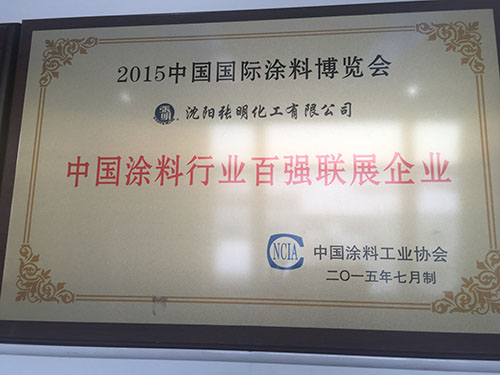

Shenyang Zhangming Chemical Co.,Ltd

Headquarters

Address:Zhangyizhan Town,Economic and Technology Development Zone,Shenyang,Liaoning,China

Post code:110177

Tel:+86-24-25441330/25422788

Fax:+86-24-89330997

www.zhangming.com.cn

sysy@zhangming.com.cn

Study on the catalytic reaction of the oxidation of octanol to ISO octanoic acid by molecular oxygen. If you feel confused about this content, pay attention to the following content!

Under the calcination temperature of 500, the Fe2O3/SiO2 catalyst with 4% loading has the best activity, and the selectivity and yield of ISO octanoic acid are 55.14% and 26.41%, respectively. On the basis of the single component catalyst, the composite oxide catalyst was prepared. It was found that Fe2O3-ZnO and ZnO-CeO2 had synergistic effect, and the activity of the catalyst was obviously improved than that of the single component catalyst. However, the activity of other two component catalysts decreased. The results showed that the conversion rate of 6 to -4%Zn was 55.62%, the selectivity and yield of ISO octanoic acid were 63.66% and 35.41%, and the conversion of 6%Zn-4 to ISO octyl alcohol was 52.83%, and the selectivity and yield of ISO octanoic acid were 68.73% and 36.31% respectively. The catalysts were characterized by XRD, BET and SEM, and the relationship between the surface structure and the catalyst performance was analyzed. The process conditions for the oxidation of ISO octanoic acid with ISO octyl alcohol were studied. The effects of the amount of catalyst, reaction temperature and reaction time on the results were investigated. The optimum process conditions were as follows: catalyst dosage 4%, reaction temperature 120, reaction time 7 hours. The stability of the catalyst was investigated after recovery.

According to the experimental data, the kinetics and reaction mechanism of the catalytic oxidation of ISO octanoic acid by octanol were discussed.

Study on the catalytic reaction of the oxidation of octanol to ISO octanoic acid by molecular oxygen. If you feel confused about this content, pay attention to the following content!

Under the calcination temperature of 500, the Fe2O3/SiO2 catalyst with 4% loading has the best activity, and the selectivity and yield of ISO octanoic acid are 55.14% and 26.41%, respectively. On the basis of the single component catalyst, the composite oxide catalyst was prepared. It was found that Fe2O3-ZnO and ZnO-CeO2 had synergistic effect, and the activity of the catalyst was obviously improved than that of the single component catalyst. However, the activity of other two component catalysts decreased. Isooctanoic acid, driers, degreased naphthenic acid. The results showed that the conversion rate of -4%Zn to 6? 55.62% isooctyl alcohol, octanoic acid, selectivity and yield of 63.66% and 35.41%; 6%Zn-4? 52.83% of isooctyl alcohol conversion rate, selectivity and yield of isooctanoic acid 68.73% and 36.31%. The catalysts were characterized by XRD, BET and SEM, and the relationship between the surface structure and the catalyst performance was analyzed. The process conditions for the oxidation of ISO octanoic acid with ISO octyl alcohol were studied. The effects of the amount of catalyst, reaction temperature and reaction time on the results were investigated. The optimum process conditions were as follows: catalyst dosage 4%, reaction temperature 120, reaction time 7 hours. The stability of the catalyst was investigated after recovery.

According to the experimental data, the kinetics and reaction mechanism of the catalytic oxidation of ISO octanoic acid by octanol were discussed.